Measurement resources selection is a key issue in measurement process planning. As dimensional measuring equipment (DME) becomes available in ever-broadening ranges of versatility, accuracy, and complexity; however, optimization of resources selection for a supplier network becomes increasingly difficult. Dimensional Measuring Equipment (DME) is hardware and software used in a measurement process, e.g., a coordinate measuring machine, fixture, gage, probe, probe extension, stylus, probe tip, laser scanner, tracker, or theodolite. The selection is based on characteristics, tolerances, and datums of a part design. DME with optimized accuracy, versatility, and complexity will enable metrologists to measure dimensional and geometric characteristics of a part with less uncertainty, time, and costs. Consistently selecting the right measurement resources is the goal of all the Original Equipment Manufacturers (OEMs). Measurement process planners usually create rules to help selecting appropriate DME.

Measurement resources selection is a key issue in measurement process planning. As dimensional measuring equipment (DME) becomes available in ever-broadening ranges of versatility, accuracy, and complexity; however, optimization of resources selection for a supplier network becomes increasingly difficult. Dimensional Measuring Equipment (DME) is hardware and software used in a measurement process, e.g., a coordinate measuring machine, fixture, gage, probe, probe extension, stylus, probe tip, laser scanner, tracker, or theodolite. The selection is based on characteristics, tolerances, and datums of a part design. DME with optimized accuracy, versatility, and complexity will enable metrologists to measure dimensional and geometric characteristics of a part with less uncertainty, time, and costs. Consistently selecting the right measurement resources is the goal of all the Original Equipment Manufacturers (OEMs). Measurement process planners usually create rules to help selecting appropriate DME.

Another key issue is to determine a measurement strategy, i.e., what to measure and how to measure it. Selecting what to measure could include determining dimensional and geometric characteristics of a part in measurement processes. Characteristics include dimensions, tolerances, metrological features, and datums. Defining how to measure includes specifying where to take samples and with what dimensional-metrology systems, such as coordinate measuring machines, dimensional measurement devices, and hand-held gages. Measurement process planners usually create rules to help determining measurement strategies for features.

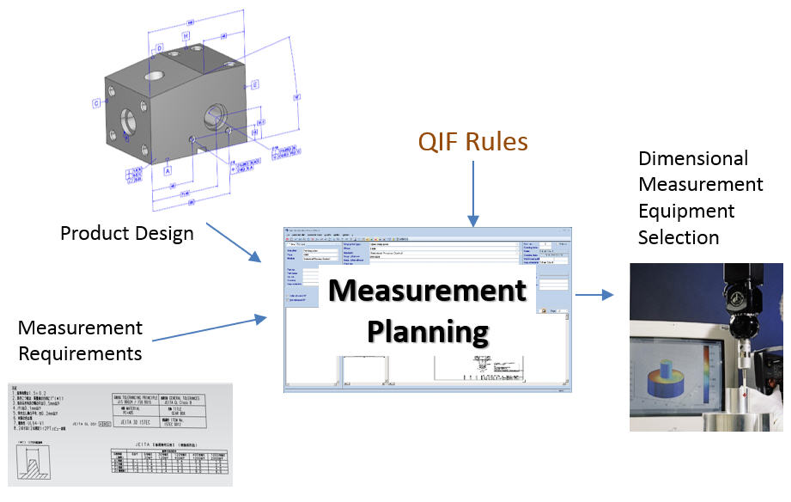

The Digital Metrology Standards Consortium’s (DMSC’s) Quality Information Framework (QIF) Rules Working Group develops Rule Types and eXtensible Markup Language (XML) Schema in the QIF standard. The goal is to develop a rule model, i.e., the standard of representing rules used in inspection process planning. The latest 3.0 version is an American National Standards Institute (ANSI) standard and was submitted to ISO/TC184/SC4 for a fast-track approval. One of the key functions in QIF is measurement rule types and XML schema, i.e., QIF Rules. These rules provide industry with a standard way of representing and sharing dimensional measurement strategy and resources selection rules in a supplier network. For example, an OEM can specify what type of coordinate measuring machine, probes, and probe tips can be used based on the tightest tolerance, smallest internal feature size, longest internal feature size, feature orientations in a setup, the part bounding box sizes in X, Y, and Z, and measurement requirements.

Part designers and quality engineers in manufacturing industry will find the QIF Rules standard useful. The standard will enable them to share Model-Based Definition/Product Manufacturing Information (MBD/PMI), measurement requirements, and measurement rules with their suppliers so that they will select capable measurement strategy and equipment to inspect dimensional characteristics of parts to ensure quality (see the figure on QIF-enable Rules Sharing).

QIF Rules Used in Measurement Planning

Contact the Author/DMSC QIF Rules Chair for more information:

Shaw C. Feng

Engineering Laboratory

National Institute of Standards and Technology

Gaithersburg, MD 20899

Email: shaw.feng@nist.gov